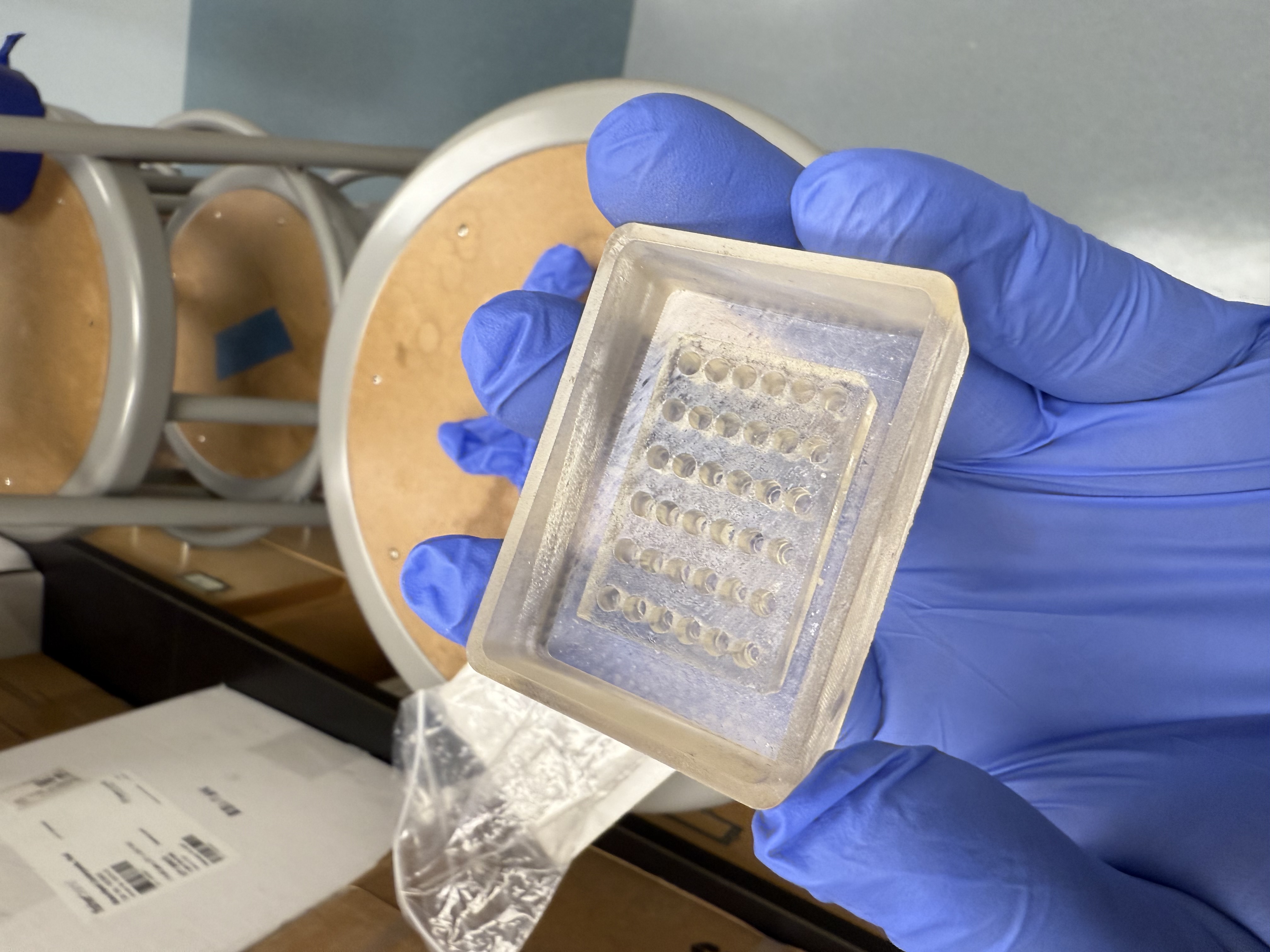

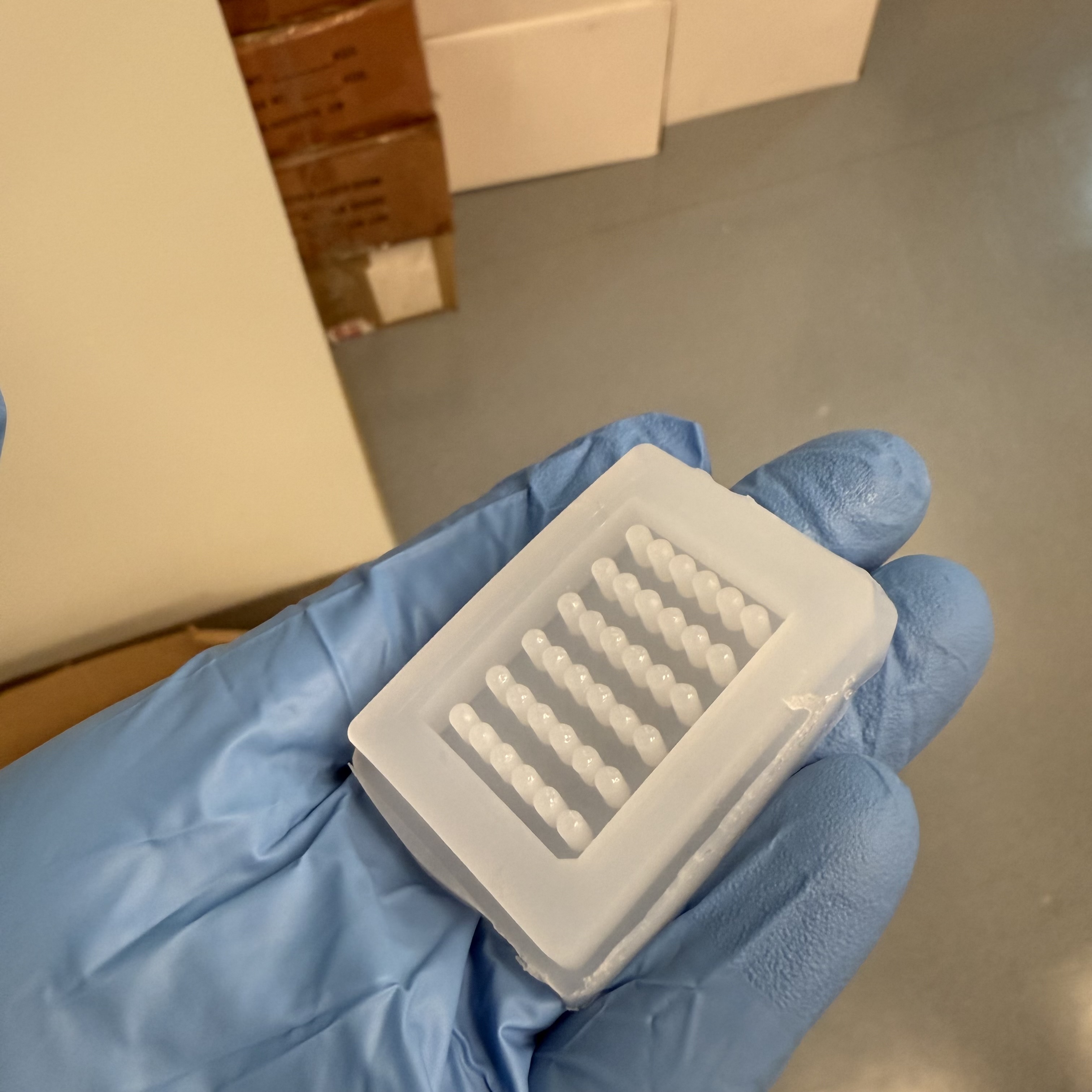

Tissue Microarray Silicone Mold

When: Oct 2025 Tags: SLA Printing, Silicone Casting, Lab Tooling

Drag to rotate • Scroll to zoom

Why build it?

Commercial silicone molds for tissue microarrays are pricey, and a PhD researcher at UC Davis asked if I could help create a lower-cost alternative. If I could knock down the price of experimentation and learn how to fabricate reliable lab molds, it felt like the kind of side project worth diving into.

The concept

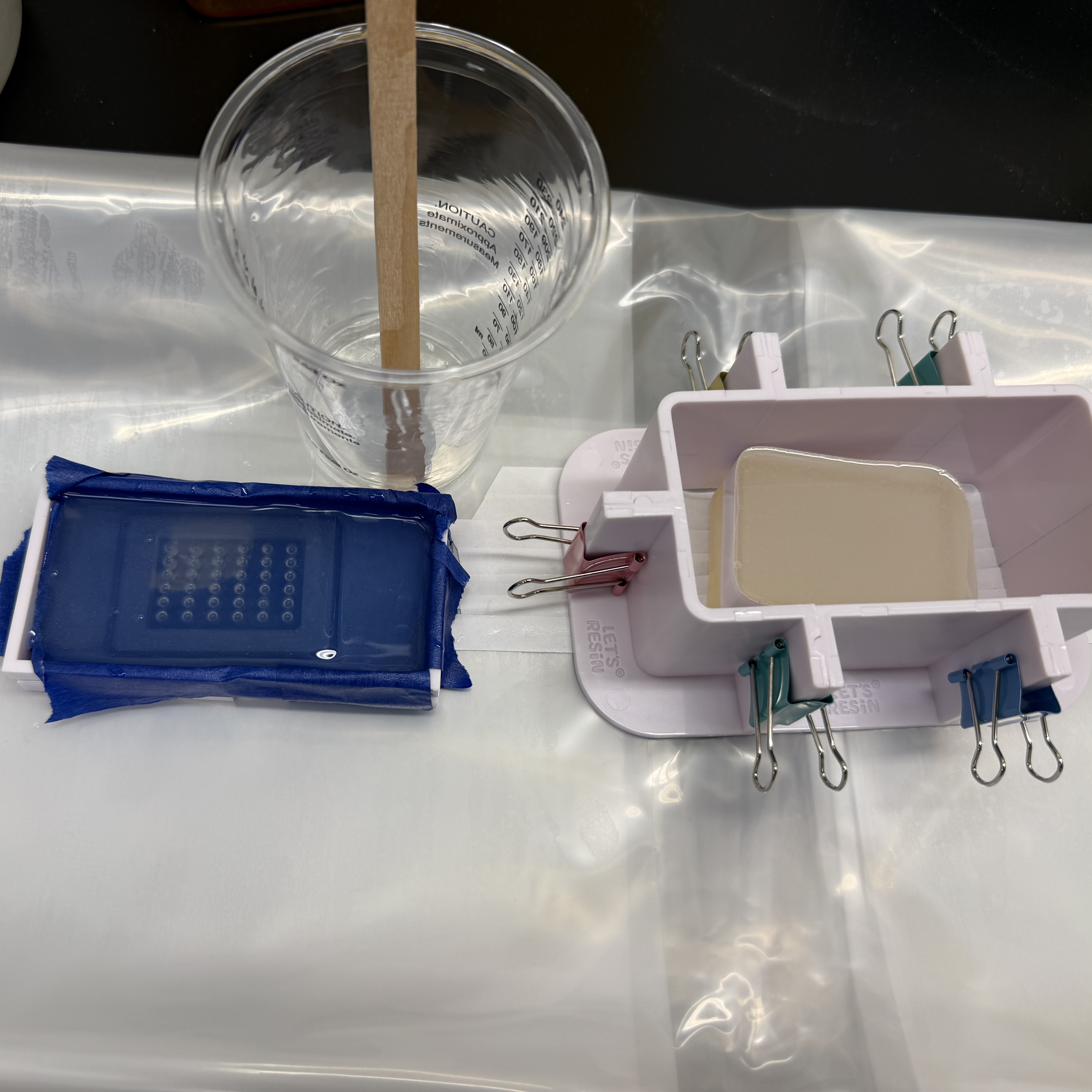

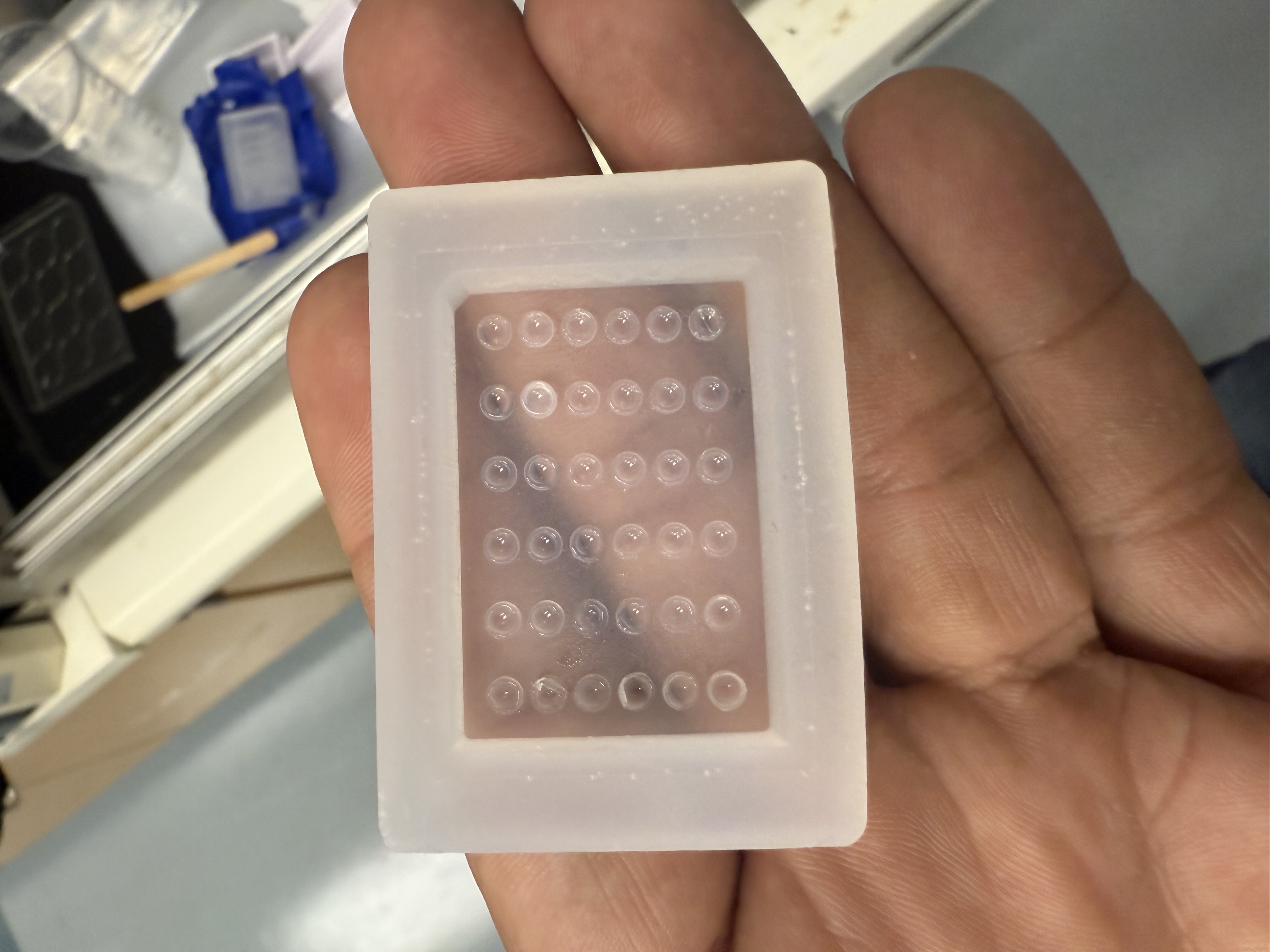

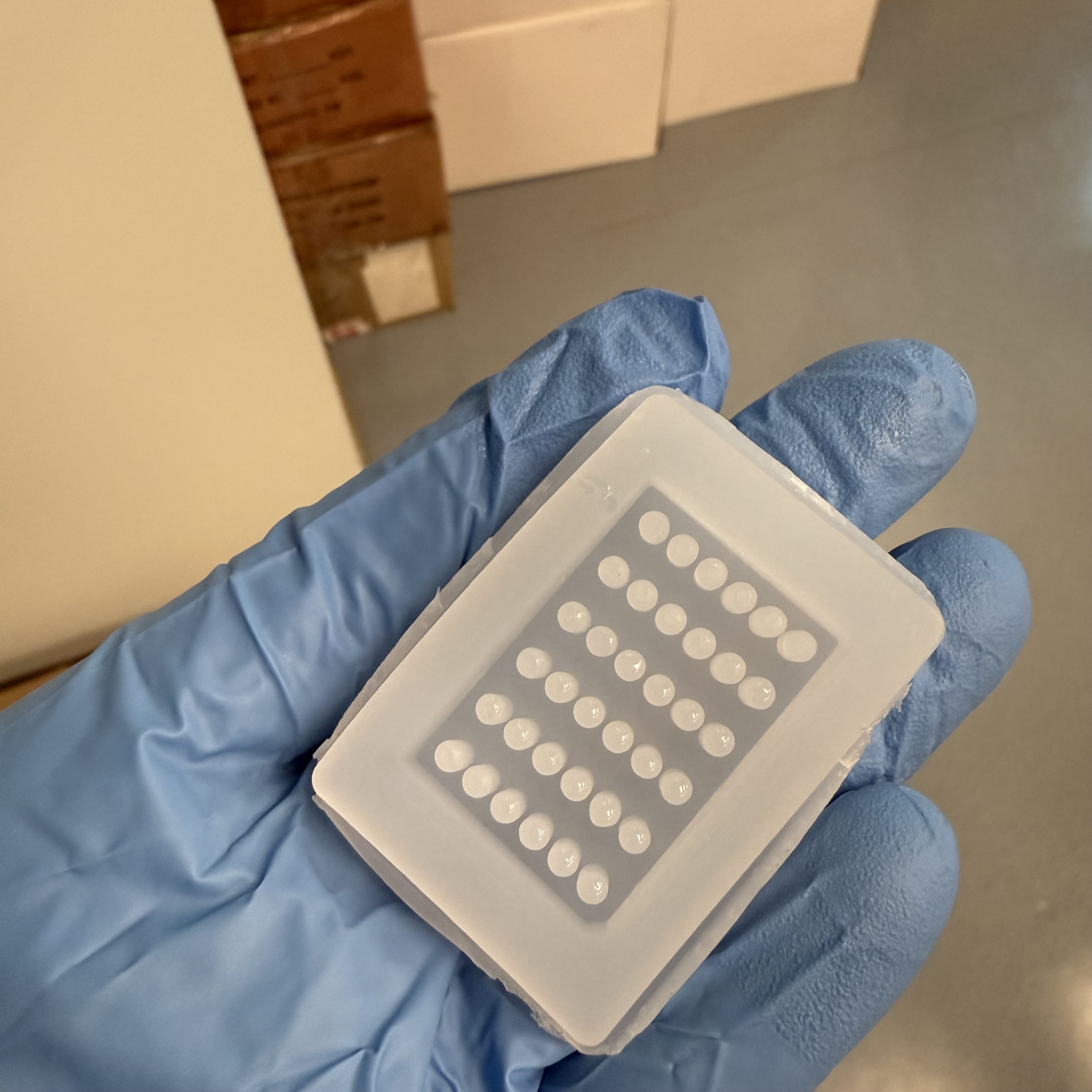

I modeled a reusable “master” mold in Shapr3D, printed it on the Elegoo Saturn 2, and post-cured it long enough that fresh silicone wouldn’t stay tacky. The idea is to pour platinum-cure silicone into the master, demold, and end up with a flexible tray that matches the dimensions labs already use for tissue cores.

Tools & materials

- Shapr3D for CAD

- Elegoo Saturn 2 with ABS-Like V3 resin (transparent)

- EZ Release spray

- Let’s Resin 15A platinum-cure silicone rubber

- IPA wash station, UV cure station, syringes for targeted pours

Early learnings

- Post-cure is everything: Any uncured resin residue interferes with the silicone crosslinking, so a thorough UV bake and warm-air dry is non-negotiable.

- Controlled pours reduce bubbles: The silicone is thick, and the core bores are tiny. Loading syringes let me fill each cavity individually and chase out trapped air.

Next steps

- Iterate on a second master design with refined tolerances.

- Apply EZ Release after each cure cycle once the master is completely dry.

- Test the silicone mold with paraffin wax pours to confirm durability.

- Explore a removable tray or ejector plate so researchers can pop samples out without stressing the mold.